Blog

Our departments at IN-EX – Project management

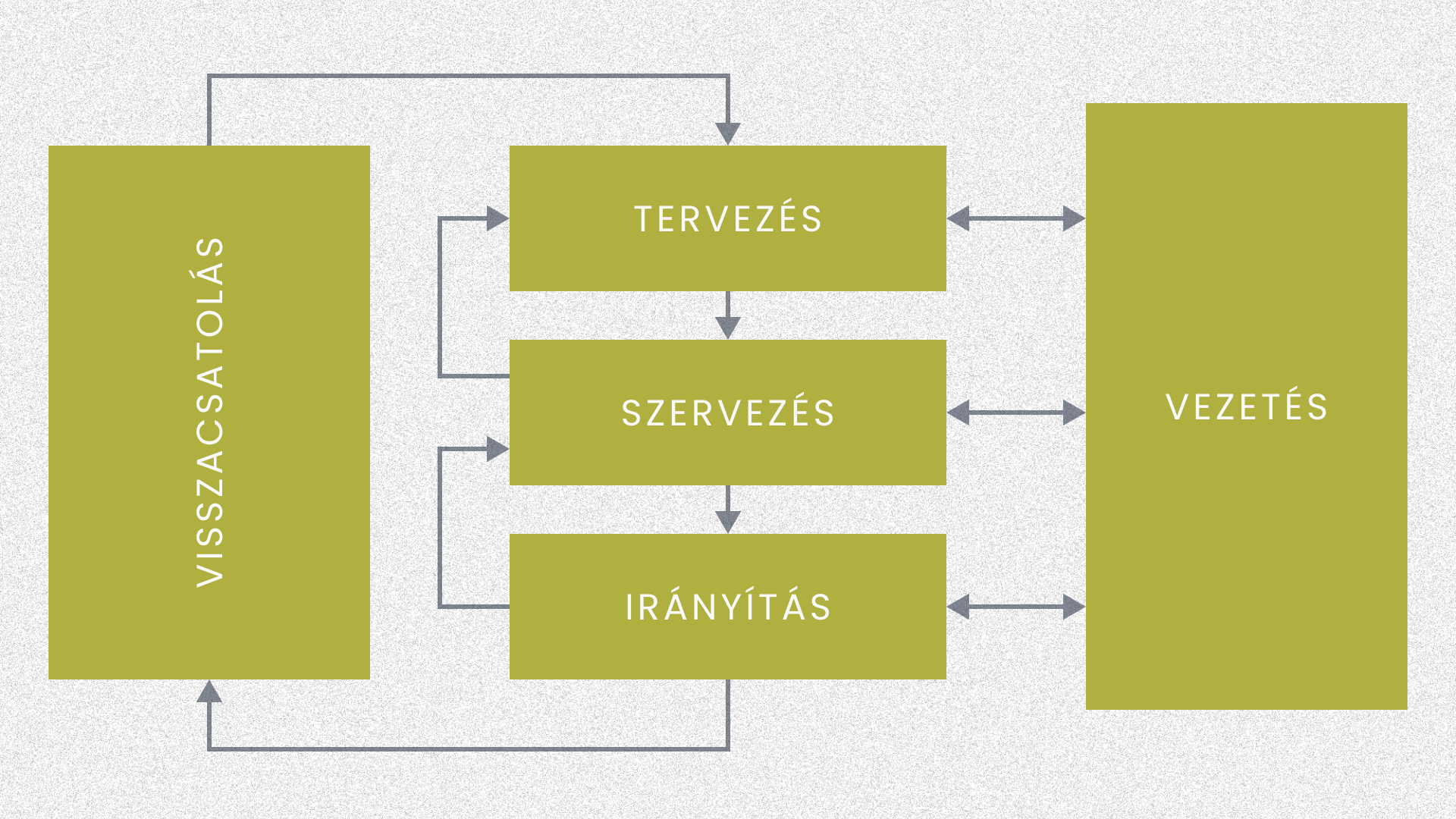

One of the strengths of IN-EX is that our design projects not only involve our highly professional engineers, but we also have a dedicated team that provides back-up support for the management of the projects. Our PM team is responsible for keeping projects on track and monitoring them. This specialized team, which is not common in design offices, can help our engineers to concentrate more on designing buildings more effectively and to have well-planned and monitored projects at the same time.

During the course of our all-round architectural design tasks, we have been confronted with the need to coordinate and to precisely organize the work of the disciplines involved in the design of a modern building, which is the key to successful, timely and efficient delivery. In the past, we have experienced several problems, extra time and costs, and especially a lot of stress due to the re-designs and the modifications, and the overtime caused by disorganized parallel design processes. The pressure, which was generated by the global economic processes have also encouraged us to improve our organizational culture in order to operate more efficiently. We have launched several internal organizational development projects, one of which was the training of design project managers and design managers, and the creation of a manual and a toolkit to support their work.

The IN-EX Project Management Manual is based on international literature, believing that having more than a decade of experience in project management cannot lead us astray. The Project Management Manual also covers the topic of risk management. In this context, our project managers participated in a risk management workshop today, where the problems and their appropriate solutions we face in our designing process were explained. After all, risk management is about managing problems and reducing the likelihood of them occurring before they happen.

At IN-EX, we place a strong emphasis on continuous improvement. The basic idea behind this is the fact that we continuously ask for feedback from our co-workers, when it comes to our designing projects. We do project evaluations on several occasions during each of our projects: we ask our co-workers for their feedback by sending them a standard questionnaire, because we need to know in which areas there is a potential to improve. During our project evaluations we receive useful feedback on development projects, for example on the design-related timing that is part of the Project Management Manual. „I believe the conscious internal scheduling made a great debut. In fact, none of the deadlines were endangered because we miscalculated the duration of the workflow. On the architectural side, we carried out a meticulous analysis. Almost no detail was overlooked and all the tasks had an owner and a specific deadline. “

Recent posts

What is the fundamental difference between additional and supplementary work?

We celebrated one of the happiest days of Spring at STUDIO IN-EX: it was the MUTIHOLDOLGOZOL DAY, also known as “Show me where you work”, when children could enter the world of adults, specifically the exciting universe of architects, mechanical, electrical and structural engineers.

Show us where you work – A day at STUDIO IN-EX through the eyes of children

We celebrated one of the happiest days of Spring at STUDIO IN-EX: it was the MUTIHOLDOLGOZOL DAY, also known as “Show me where you work”, when children could enter the world of adults, specifically the exciting universe of architects, mechanical, electrical and structural engineers.

Hydro Extrusion – Office with a Minimalist Design

Hydro Extrusion Hungary Kft. is a subsidiary of a Norwegian parent company, so an important aspect of the interior design process was to ensure that the minimalist aesthetic and the company’s brand colors are harmoniously reflected throughout the interior spaces.

Professional day for students of civil engineering

Students from Zielinski Szilárd College of Civil Engineering have just participated in an exciting professional visit to the STUDIO IN-EX general design office.

Final exams at the BME

Thanks to the Faculty of Civil Engineering, Zsolt Oláh was invited to be an external committee member for the MSc in MSc in Construction Information Technology Engineering to review the students' thesis and attend their final exams.

Hydro Extrusion’s solutions: heat dissipation

By Hydro's aluminium foundry project presented us with an unusual design challenge. We have strong acoustic requirements to protect the neighbourhood, and that the furnaces generate a lot of heat, which we had to dissipate while minimising noise.