Blog

A support structure design challenge: the Danish plastic toy manufacturing and packaging plant

We have completed the construction of one of our design projects from 2020. In this post we present one of the four main buildings of the complex, a 9,000m2 packaging plant. The construction of the building started in mid-2021 and was completed in the first quarter of 2023. STUDIO IN-EX was asked to be the general designer for the construction designs and to support the construction of the buildings in the framework of a design engineer’s site supervision.

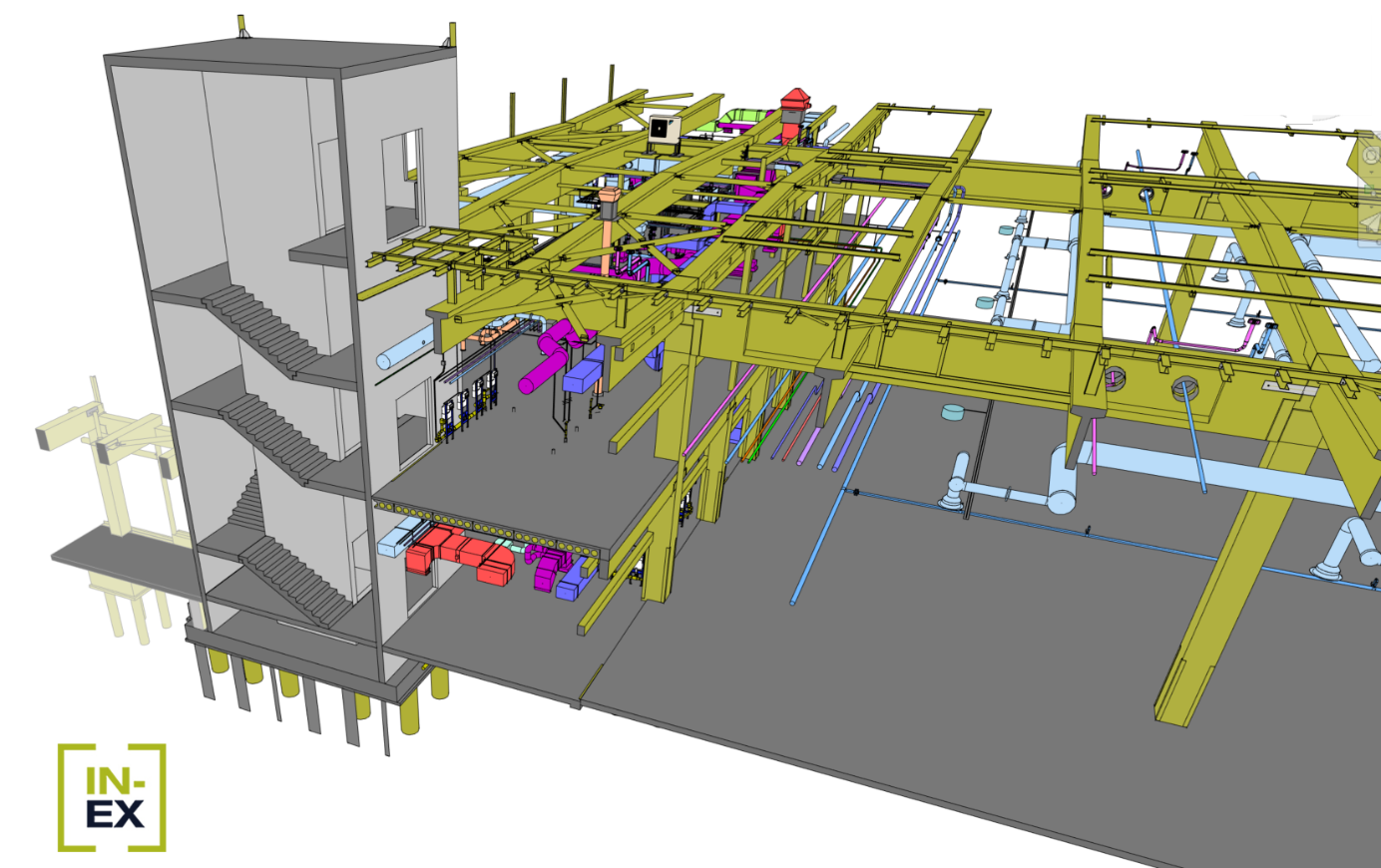

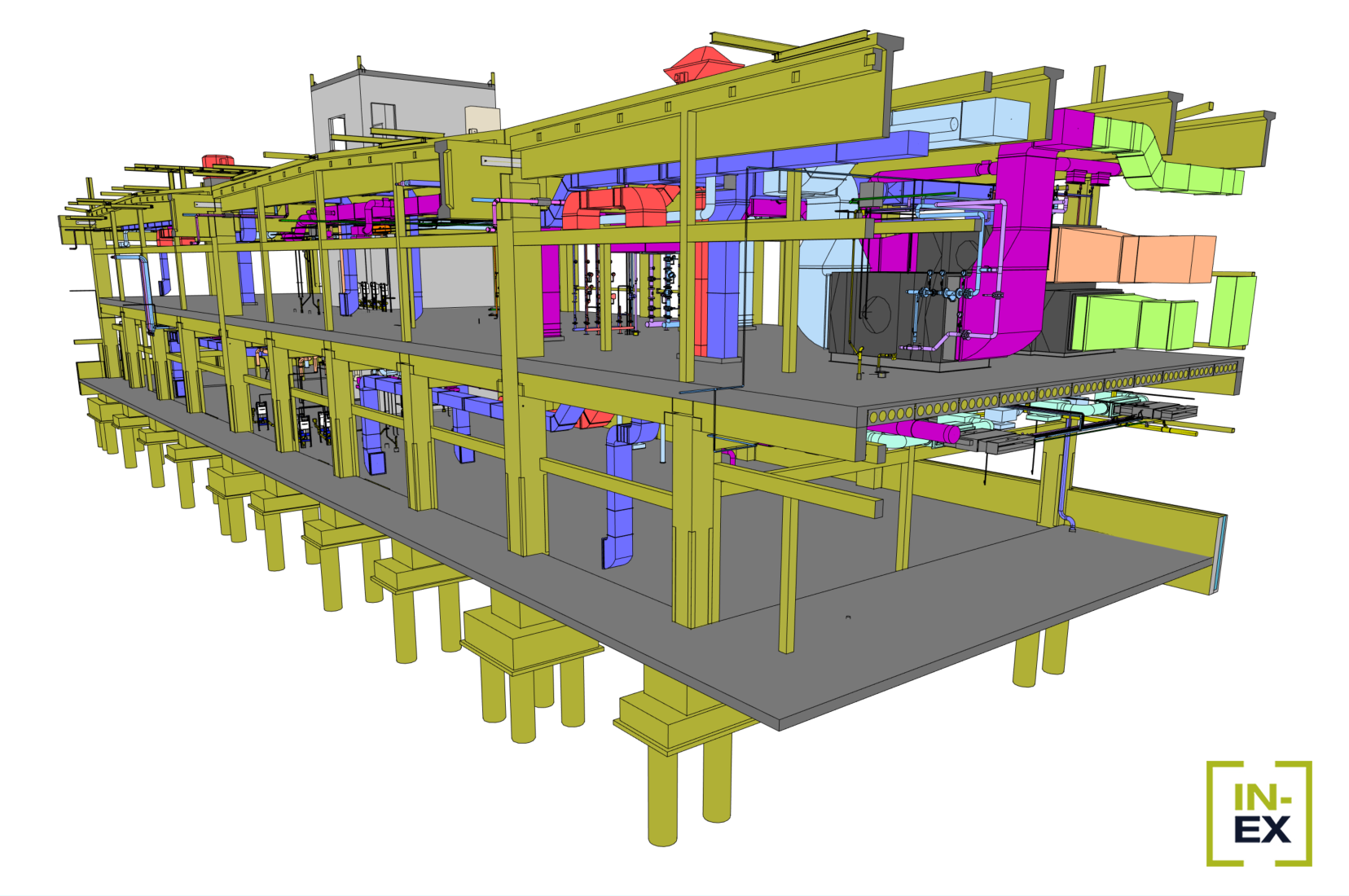

The fact that all disciplines work in the same space in our office was a great advantage during the design process, as it required constant collaboration between the design studios. Our designers all work on a common platform, a closed-BIM system, which makes their work extremely efficient. Any modifications to the structure were immediately reflected in the model, making them traceable in minutes during the design process. In all cases, the construction designs are submitted to the construction company after several rounds of clash detection in order to minimise construction errors. In addition to the 8,000m2 of packaging technology in the hall area, the main function is served by a 2×1,000sqm two-storey workshop and an office block.

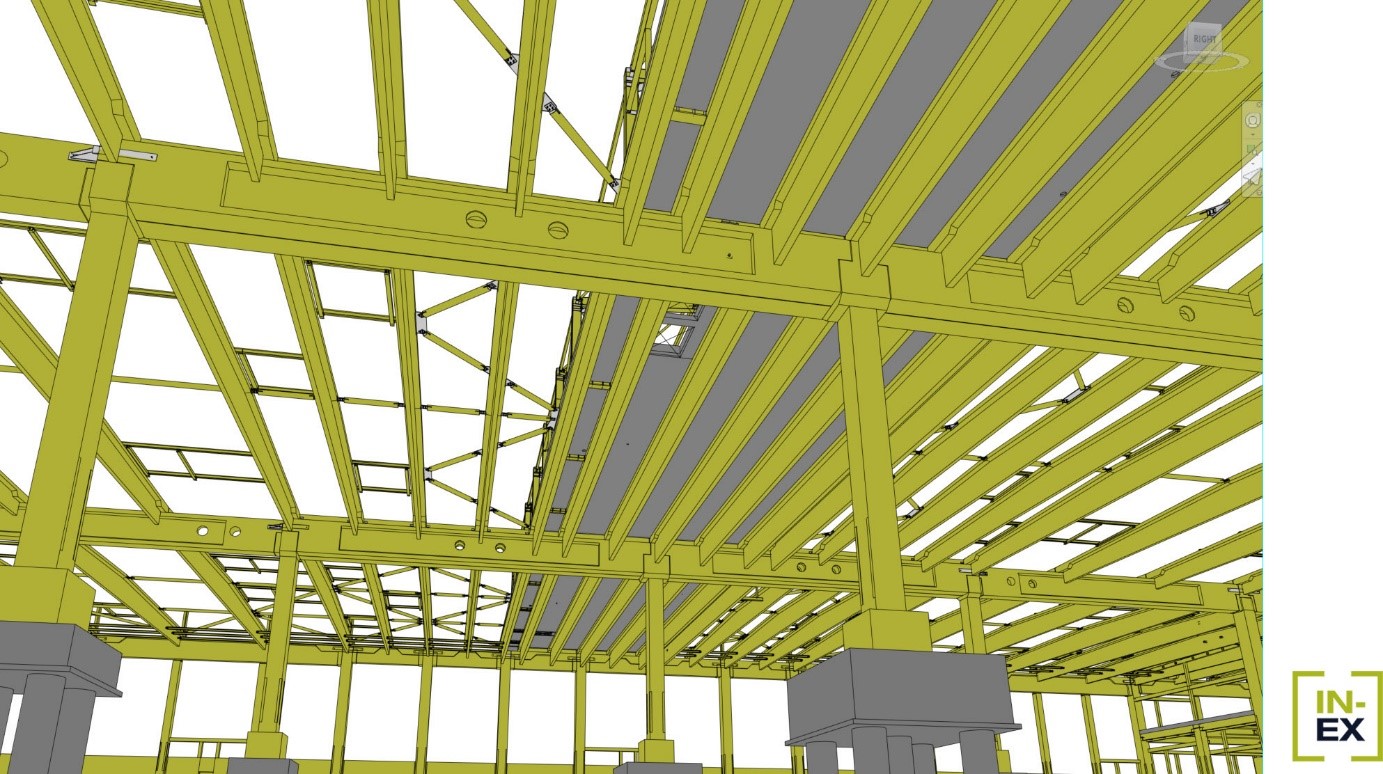

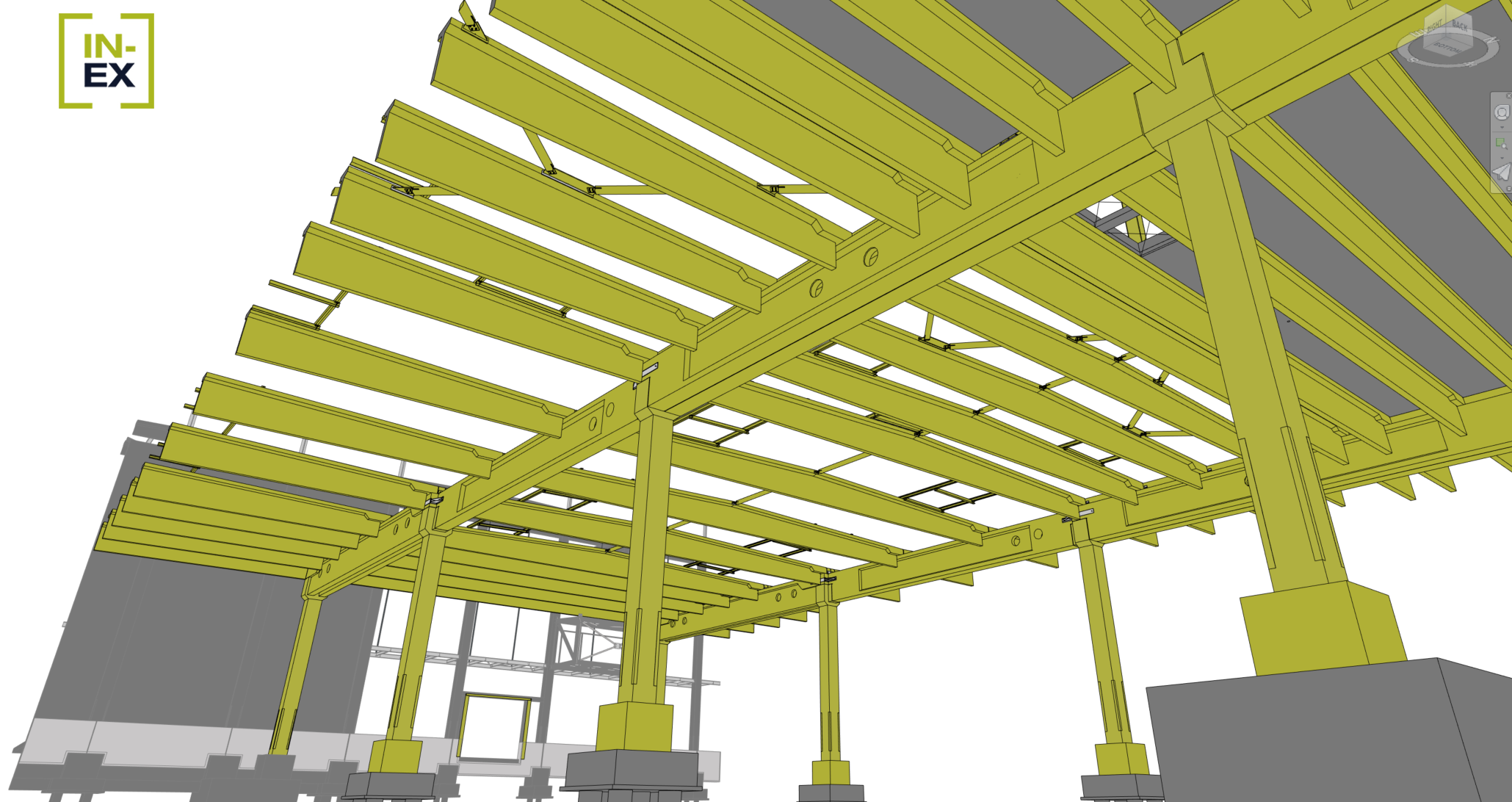

IIt was a real challenge for our structural engineers: The building is a precast reinforced concrete frame structure with pile foundations. The service headquarters was also built with a prefabricated frame slab floor consisting of hollow core slabs. The main vertical load-bearing element of the structure are the 75x75cm columns, which are supported by 120cm high prefabricated pocket necks, which also stiffen the hall in the horizontal direction. The roof structure consists of a series of 150cm high spine purlins with a span of 26.5m-23.8m-26.5m and 165cm high main beams with a span of 18.0m.

On the roof structure, 10.5m above the central section of the hall area, there is a steel-framed mechanical superstructure with a reinforced concrete slab, which houses three 9-ton air handling machines. The roof level with its superstructure and mechanical systems was subjected to significant loads, and we had to cope with the increased stresses from the earthquake during the designing.

Author: Norbert Ábelovszki, Head of the Structural Design Team

Recent posts

Introduction to Electrical Design in University Education

The building electricity design project at the Kandó Kálmán Faculty of Electrical Engineering at Óbuda University provides an excellent opportunity for students to gain practical experience. Once students have completed their educational project, they will have the opportunity to join our internship programme.

#mutiholdolgozol day (Showuswhereyouwork) in our office

On 3 April, we held a very special day at our architects' office, in connection with the #mutiholdolgozol campaign. It was a day where the children of our staff could get an insight into our work and experience what their parents' workday looks like.

Automating AHU Family Creation

Our collaboration with Rosenberg Gmbh exemplifies our dedication to delivering customized solutions that enhance the efficiency of Air Handling Unit (AHU) design for mechanical engineers. Through careful planning and expertise, we've crafted a tailored tool that simplifies the integration of AHU designer software with Revit content, easing the workload for mechanical engineers collaborating with Rosenberg Gmbh

NOT-SO-FANTASTIC ARCHITECTS AND WHERE TO FIND THEM

Last week, our colleagues took part in another career orientation day entitled NOT-SO-FANTASTIC ARCHITECTS AND WHERE TO FIND THEM, presenting the designing profession to the interested students of Babits Mihály Gimnázium.

We participated at a Professional Expo at BME’s Cultural and Professional day

Our engineers participated at BME’s Cultural and Professional day, which was organized by BME's Faculty of Civil Engineering.

Our BIM Studio leader presented at a BIM Talk Event

In November, the KÉSZ Group held its BIM Talk Event, where professionals within the Group interested in BIM took part in high quality presentations and participated in interactive round table discussions. Zsolt Oláh, STUDIO IN-EX’s BIM Studio leader was invited as a presenter.