Blog

IN-EX: in-house key disciplines – The simulation of heat and smoke propagation

Today, the issue of ensuring a cost-effective energy supply, especially for industrial buildings that are used for production, is becoming much more important than ever before.

Today, the issue of ensuring a cost-effective energy supply, especially for industrial buildings that are used for production, is becoming much more important than ever before.

One possible answer is to add solar panels to the electricity grid, but to achieve significant energy savings requires the installation of a significant amount of equipment, requiring a significant amount of space. An obvious solution may be to cover the roof with solar panels, but in addition to the numerous mechanical devices on the roof, the installation of these panels may also be complicated by the heat and smoke extraction domes, which are inevitable from the perspective of fire safety.

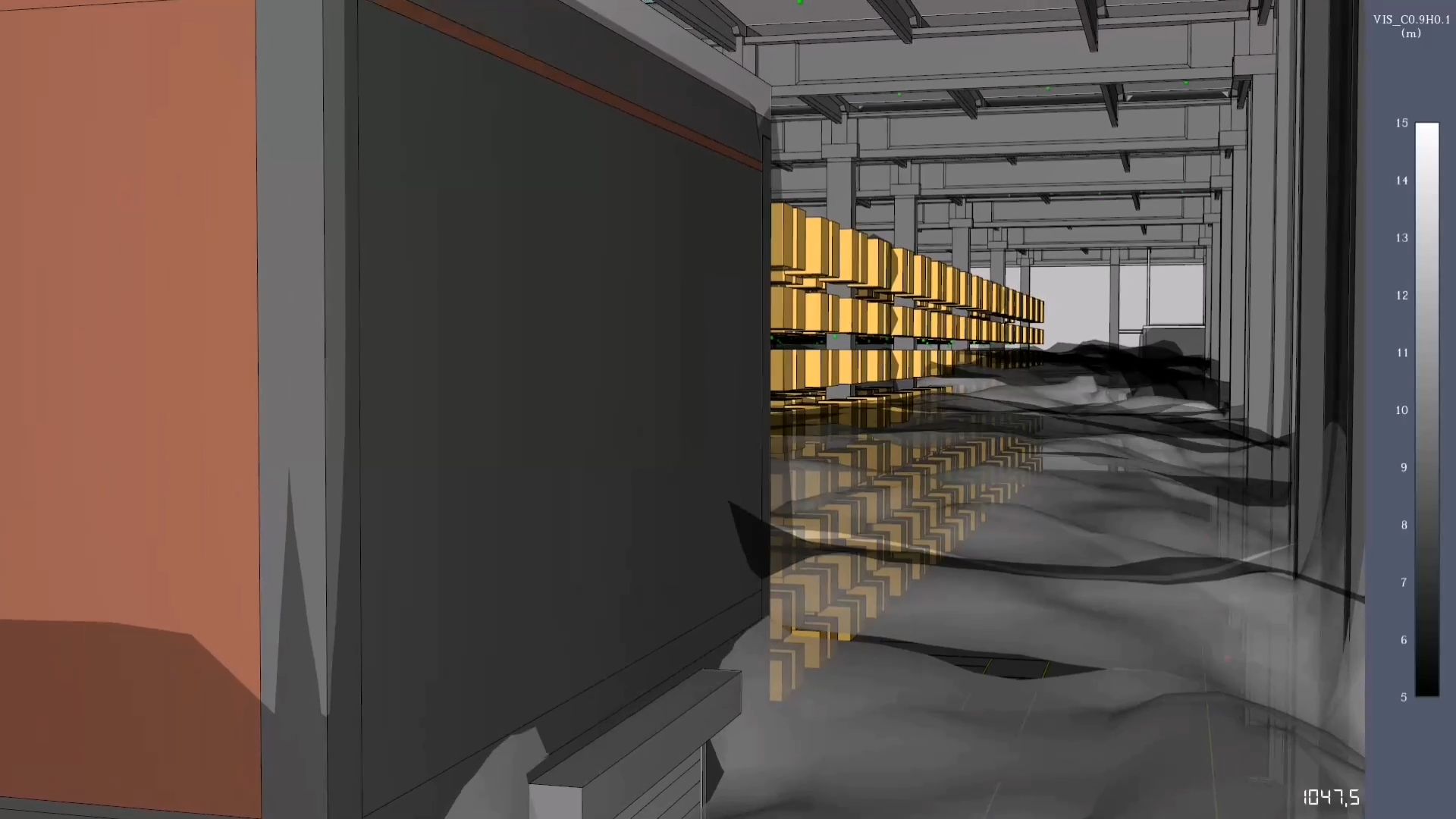

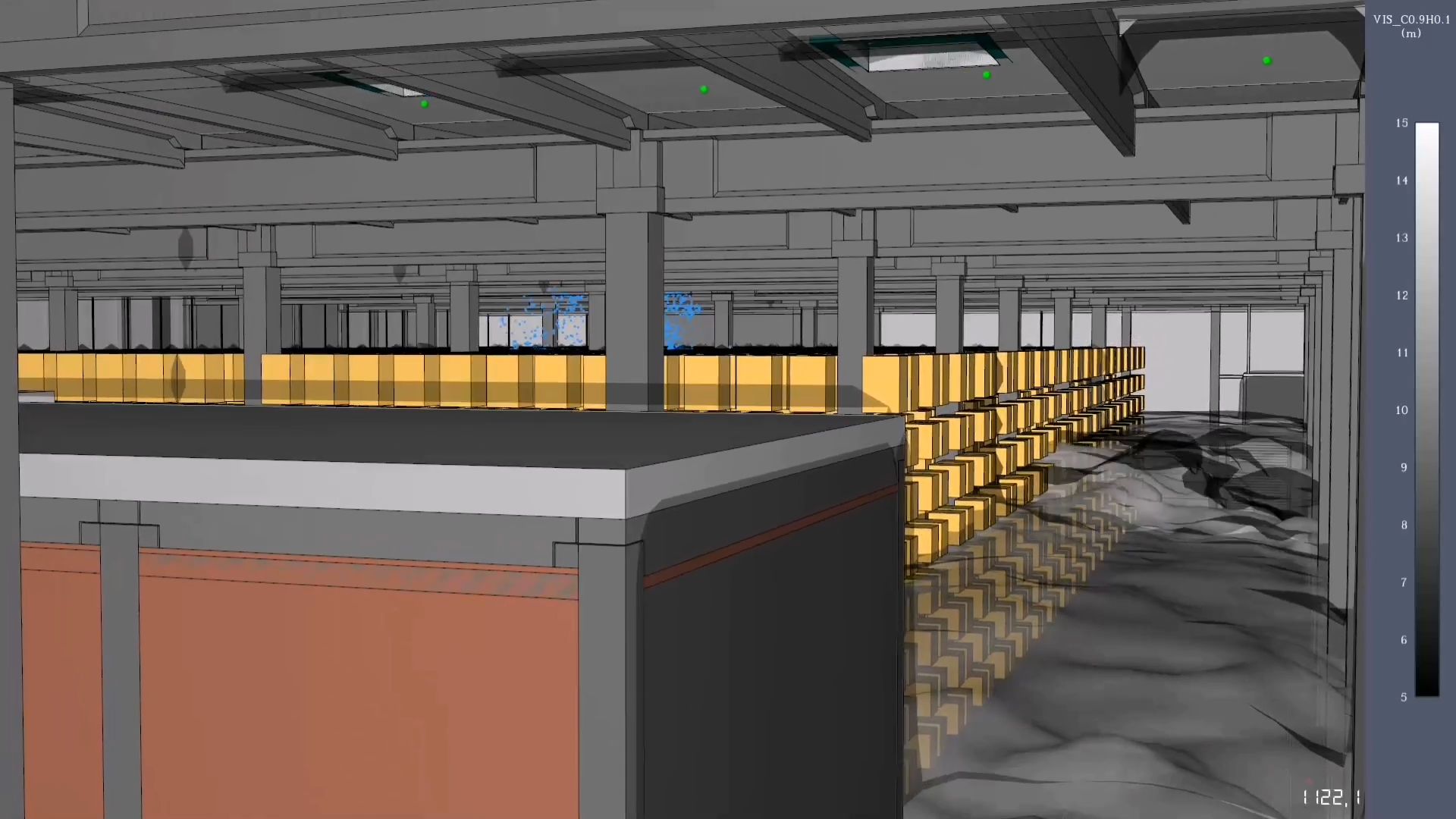

The National Fire Safety Code and the relevant Technical Guidelines for Fire Safety specify the exact effective opening areas required, but if we can simulate that the heat and smoke extraction is effective even at smaller sizes, the opening areas, and thus the number of domes, can be reduced by half. During the simulation, fires with high smoke development potential are set in the most unfavourable locations for intervention, and then it is checked whether the firefighting intervention conditions are met, taking into account the spreading and the opening times. This can be seen in the video below.

If it can be demonstrated to the authority that no temperatures are generated that would endanger the people trying to escape or would cause the ignition of additional materials, and no smoke concentrations are generated that would prevent firefighters from being able to approach the fire, there is no obstacle to the use of reduced surfaces. Thanks to the professionalism of our colleagues and our state-of-the-art IT tools, we can now carry out these tests in-house.

Recent posts

What is the fundamental difference between additional and supplementary work?

We celebrated one of the happiest days of Spring at STUDIO IN-EX: it was the MUTIHOLDOLGOZOL DAY, also known as “Show me where you work”, when children could enter the world of adults, specifically the exciting universe of architects, mechanical, electrical and structural engineers.

Show us where you work – A day at STUDIO IN-EX through the eyes of children

We celebrated one of the happiest days of Spring at STUDIO IN-EX: it was the MUTIHOLDOLGOZOL DAY, also known as “Show me where you work”, when children could enter the world of adults, specifically the exciting universe of architects, mechanical, electrical and structural engineers.

Hydro Extrusion – Office with a Minimalist Design

Hydro Extrusion Hungary Kft. is a subsidiary of a Norwegian parent company, so an important aspect of the interior design process was to ensure that the minimalist aesthetic and the company’s brand colors are harmoniously reflected throughout the interior spaces.

Professional day for students of civil engineering

Students from Zielinski Szilárd College of Civil Engineering have just participated in an exciting professional visit to the STUDIO IN-EX general design office.

Final exams at the BME

Thanks to the Faculty of Civil Engineering, Zsolt Oláh was invited to be an external committee member for the MSc in MSc in Construction Information Technology Engineering to review the students' thesis and attend their final exams.

Hydro Extrusion’s solutions: heat dissipation

By Hydro's aluminium foundry project presented us with an unusual design challenge. We have strong acoustic requirements to protect the neighbourhood, and that the furnaces generate a lot of heat, which we had to dissipate while minimising noise.