Blog

Orchestra rehearsal room as an instrument

The Competition team was established almost a year ago within Studio IN-EX in order to provide the opportunity for our adventurous collegaues to take part in international architectual tenders.

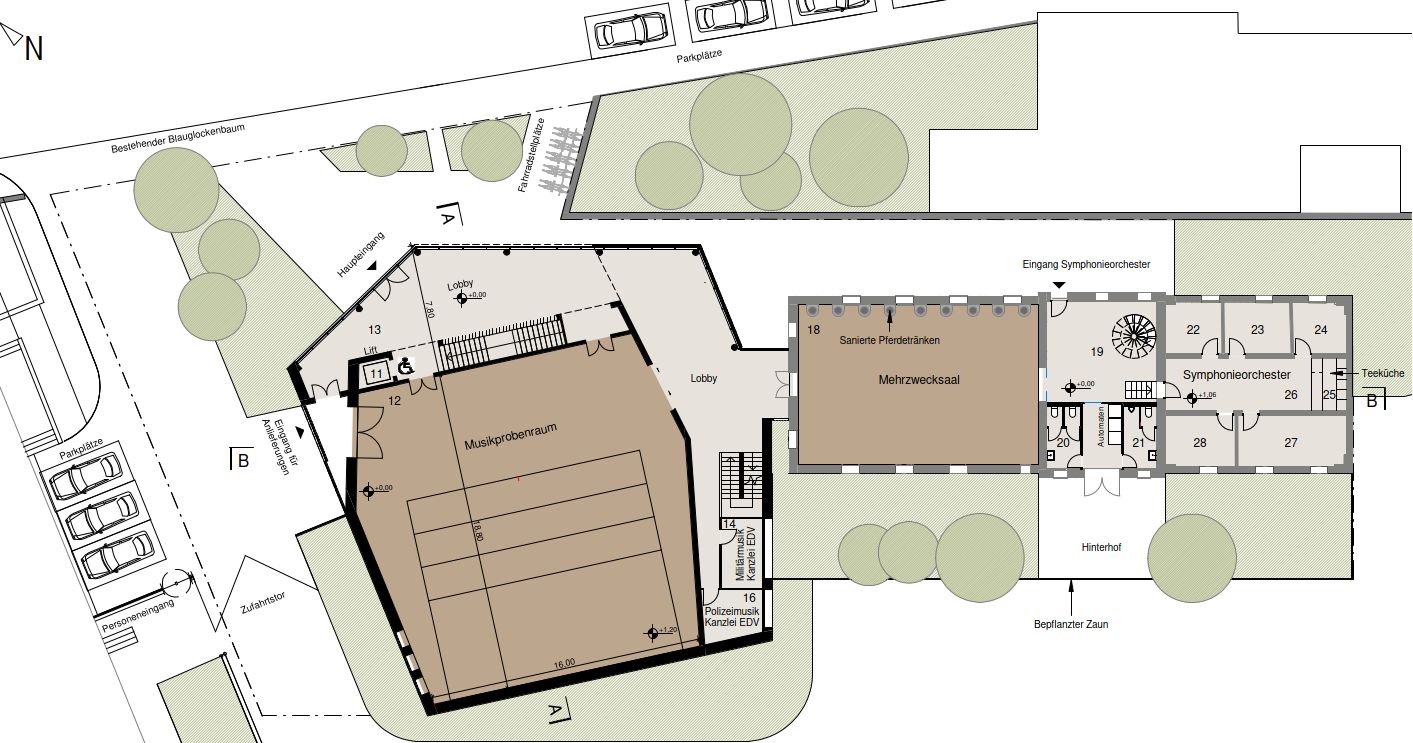

Their first job was an Austrian competition/application. The Musikprobenzentrum building was designed in the city of Bergenz by renovating the old monumental riding-school.

The building complex is a modern orchestra rehearsal room, which gives place for the Vorarlberg military band, the police band and for the regional symphony orchestra to perform, but at the same time it is used by the Bregenz conservatory and other civil orgainzations.

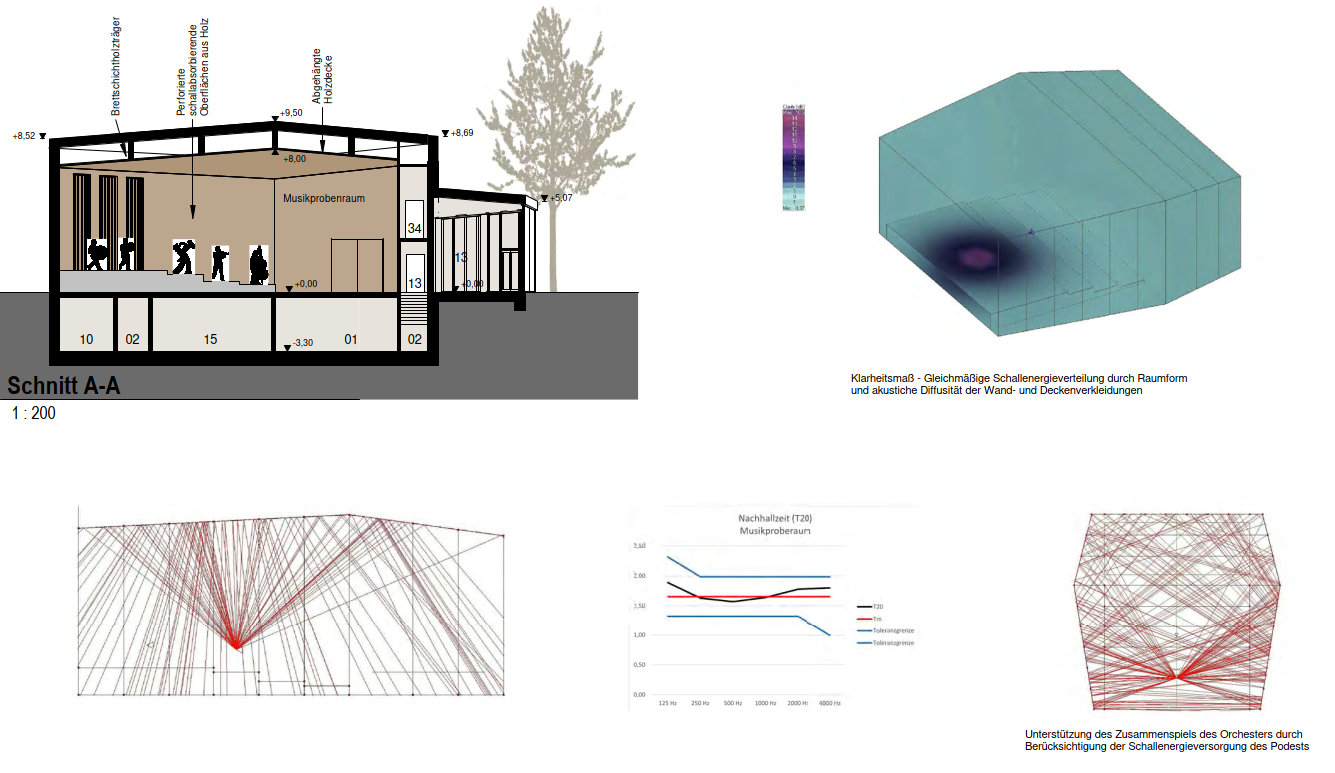

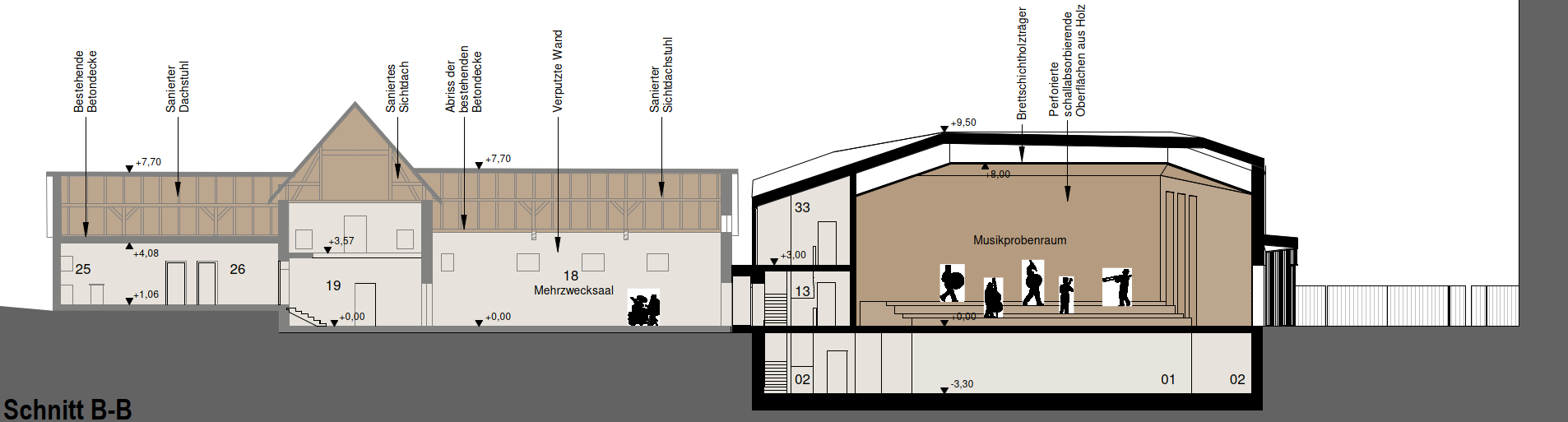

The fraction of the rehearsal room determins the shape of the building. As an instrument’s reasonating body amplifies the sound giving a unique character to the music it comes to life in the rehearsal room. According tot he calculations of the acoustic model, that was prepared for the premise the instrumants have a flat sound in the hall, so every musician will appropriately hear the sound of every instrument. This results in an outstanding sound quality for rehearsals and possible concerts.

By joining to the remaining rossstal monument and renovatiing it we keep the past/history (nem tudom mi lenne itt a helyesebb) close by renovating the wooden roof, renovating and introducing the remaining stone ló itató and by keeping the special metal grill takarmánytálcák, that will hold place for keeping musical sheets (ebbe a mondatba nagyon belezavarodtam). We plan to use tried and tested building materials, which are not harmful for health for the sustainable renovation of the remaining building and for the sustainable construction of the new building (lehet ezt sem jól fordítottam). The new building’s construction is using regional wooden materials the curtain walls are made of recycled steel. The walls and the ceiling of the warm atmosphered main places are enfolded with an acoustic wooden sheet.

„And people come together sometimes soldiers, sometimes police officers, sometime scholars and sometimes all of them. And they perform, the sound of their instruments fills every corner of the place. They play with pleasure”.

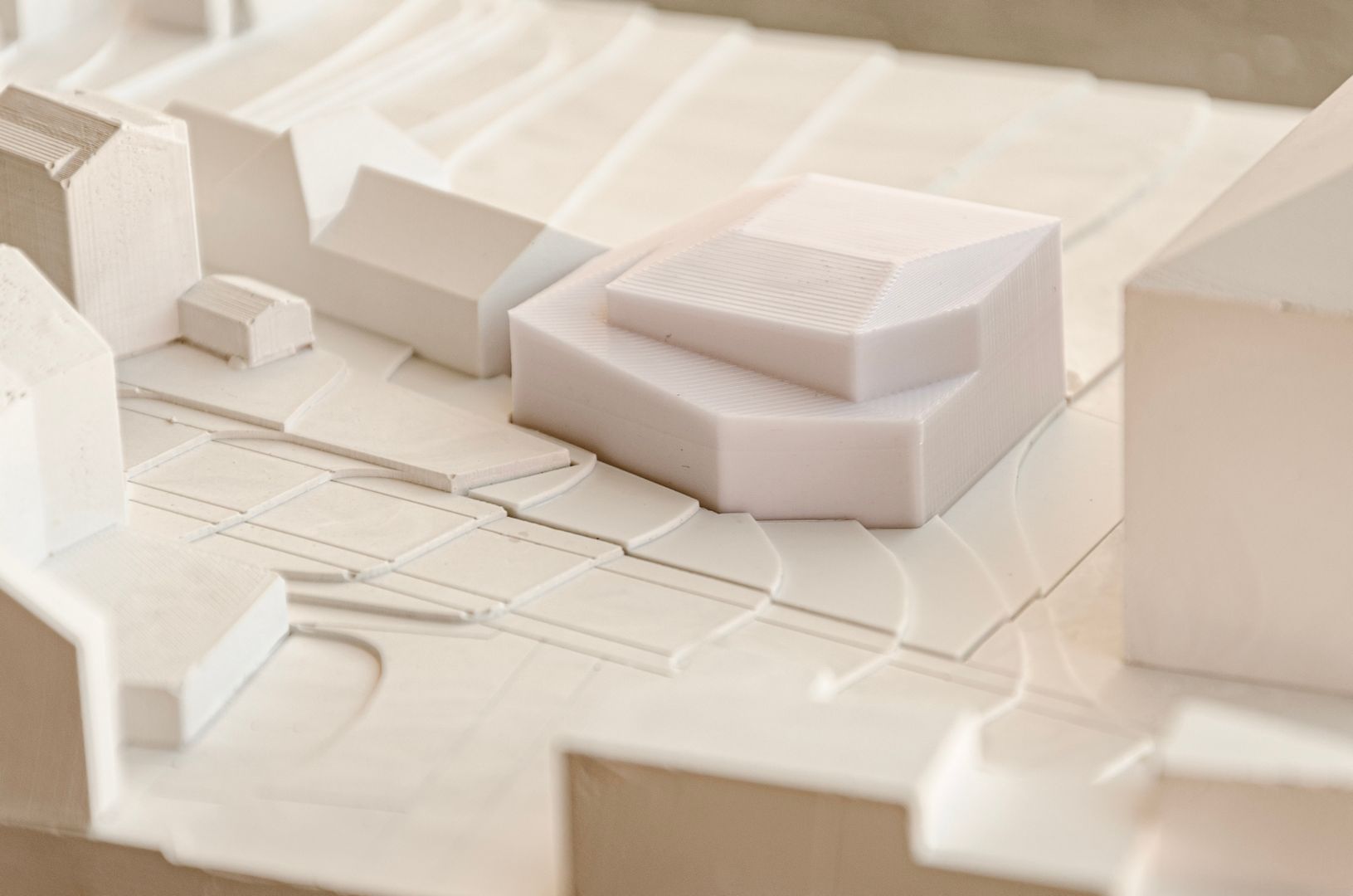

The application vriters sent a pre-built gypsum model of the whole area, where the exact location of the designed building was pre-determined. We had to place the 3D printed version of the concept in this maquet and return the completed model.

What is interesting about this building is that it was completely designed by using Revit and none other graphical programes were used.

Architects:

Sándor Jassó

Péter Krámer

Barbara Csillik

Dominika Hevér

Anna Istók

Yuliia Shyrobokykh

Diana Arenas

Gábor Szász

Ádám Nagy

Adrienn Bársony

Borbála Kis

András Kovács

Acoustic designer:

Zsuzsanna Alabárdos

3D printing:

István Ozsváth

German translation

Enikő Szivek

Recent posts

What is the fundamental difference between additional and supplementary work?

We celebrated one of the happiest days of Spring at STUDIO IN-EX: it was the MUTIHOLDOLGOZOL DAY, also known as “Show me where you work”, when children could enter the world of adults, specifically the exciting universe of architects, mechanical, electrical and structural engineers.

Show us where you work – A day at STUDIO IN-EX through the eyes of children

We celebrated one of the happiest days of Spring at STUDIO IN-EX: it was the MUTIHOLDOLGOZOL DAY, also known as “Show me where you work”, when children could enter the world of adults, specifically the exciting universe of architects, mechanical, electrical and structural engineers.

Hydro Extrusion – Office with a Minimalist Design

Hydro Extrusion Hungary Kft. is a subsidiary of a Norwegian parent company, so an important aspect of the interior design process was to ensure that the minimalist aesthetic and the company’s brand colors are harmoniously reflected throughout the interior spaces.

Professional day for students of civil engineering

Students from Zielinski Szilárd College of Civil Engineering have just participated in an exciting professional visit to the STUDIO IN-EX general design office.

Final exams at the BME

Thanks to the Faculty of Civil Engineering, Zsolt Oláh was invited to be an external committee member for the MSc in MSc in Construction Information Technology Engineering to review the students' thesis and attend their final exams.

Hydro Extrusion’s solutions: heat dissipation

By Hydro's aluminium foundry project presented us with an unusual design challenge. We have strong acoustic requirements to protect the neighbourhood, and that the furnaces generate a lot of heat, which we had to dissipate while minimising noise.