Blog

Visiting a factory building site at the beginning of your professional career

The construction of several buildings of our Nyíregyháza-based project is at such a stage that the electrical team, together with the BMS team, decided it would be worth taking a look at the work in progress. At IN-EX, the management is an absolute partner in giving young, budding engineers the opportunity to gain experience outside the office, as many of us have no prior background in construction. For us, a site visit like this is an opportunity to step outside the world of computer-assisted modelling by leaving Revit behind, and to see what we design on paper looks like in reality.

As mentioned above, our visit this time was mainly focused on all things electrical. We were joined by our experienced colleagues who are currently working on the project and who made our visit more interesting: they told us about the design phases, their experiences, interesting facts, difficulties and problems that had to be solved during the design process.

As regards their function, we were able to see the work being carried out in the buildings that will be used for packaging and storage in the future, and we were particularly interested in the distribution boards. Fortunately, we were able to catch a stage of construction in which there were distribution boards that were still heavily under assembly, but we also had the opportunity to see the Okken switchboards in trial operation. It was interesting to see both states, as in both cases we were able to study the boards from different angles.

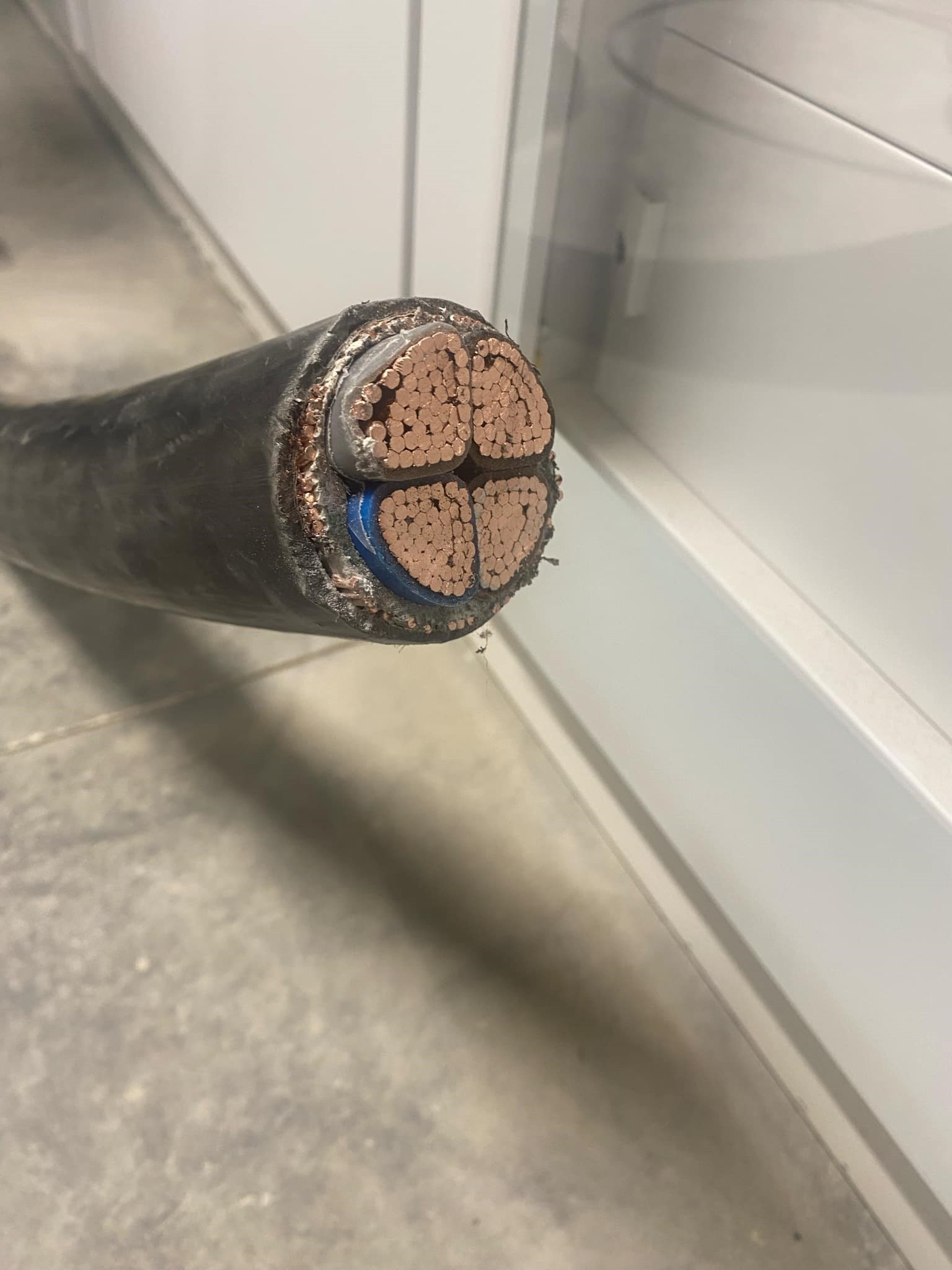

Walking around the building, we were constantly amazed at everything we saw: the monumental halls, the air handlers being assembled, or even the size of a 4×240/120 cable, which is the largest size we usually design. The really curious ones were allowed to try to lift it up; I was one of them and I have to say, those assembling and working with them metre by metre have my greatest respect.

At the end of the day, we had the chance to see a hall full of machines making plastic toys in operation. In this part of the building, in addition to the professional experience, we also had a little treat for our eyes, as we walked through the corridors and saw models of many collections, figures from a popular film or fairy tale, There was also a mock-up of the factory complex, built down to the smallest detail, which we lingered over and listened to our colleagues tell us stories about the design. In conclusion, we agreed that we would like to continue this tradition in the future and take the opportunity to visit projects under construction, where we can again expand our knowledge and become better professionals in this wonderful profession 🙂

Alexandra Takács, electrical engineer

Recent posts

What is the fundamental difference between additional and supplementary work?

We celebrated one of the happiest days of Spring at STUDIO IN-EX: it was the MUTIHOLDOLGOZOL DAY, also known as “Show me where you work”, when children could enter the world of adults, specifically the exciting universe of architects, mechanical, electrical and structural engineers.

Show us where you work – A day at STUDIO IN-EX through the eyes of children

We celebrated one of the happiest days of Spring at STUDIO IN-EX: it was the MUTIHOLDOLGOZOL DAY, also known as “Show me where you work”, when children could enter the world of adults, specifically the exciting universe of architects, mechanical, electrical and structural engineers.

Hydro Extrusion – Office with a Minimalist Design

Hydro Extrusion Hungary Kft. is a subsidiary of a Norwegian parent company, so an important aspect of the interior design process was to ensure that the minimalist aesthetic and the company’s brand colors are harmoniously reflected throughout the interior spaces.

Professional day for students of civil engineering

Students from Zielinski Szilárd College of Civil Engineering have just participated in an exciting professional visit to the STUDIO IN-EX general design office.

Final exams at the BME

Thanks to the Faculty of Civil Engineering, Zsolt Oláh was invited to be an external committee member for the MSc in MSc in Construction Information Technology Engineering to review the students' thesis and attend their final exams.

Hydro Extrusion’s solutions: heat dissipation

By Hydro's aluminium foundry project presented us with an unusual design challenge. We have strong acoustic requirements to protect the neighbourhood, and that the furnaces generate a lot of heat, which we had to dissipate while minimising noise.